Cima Cove

Prefabricated and customizable cove lighting fixtures

Design Brief

Design a system of mass producible cove lighting fixtures with parameters for customizations that will not require design efforts after initial development.

Define customization parameters

Make fixture adaptable to any interior aesthetic

Gradient of light must be smooth and subtle

Allow for simple retrofits

Create replicable assembly steps for consistent fixture outcomes

Source materials with limited lead times

Keep LEDs out of site from any viewing angle

Intro Marketing Video

Specification Sheet

This document I created provides the technical details of an individual unit. It is made up of information about the components and feature options for customers to select from.

Process

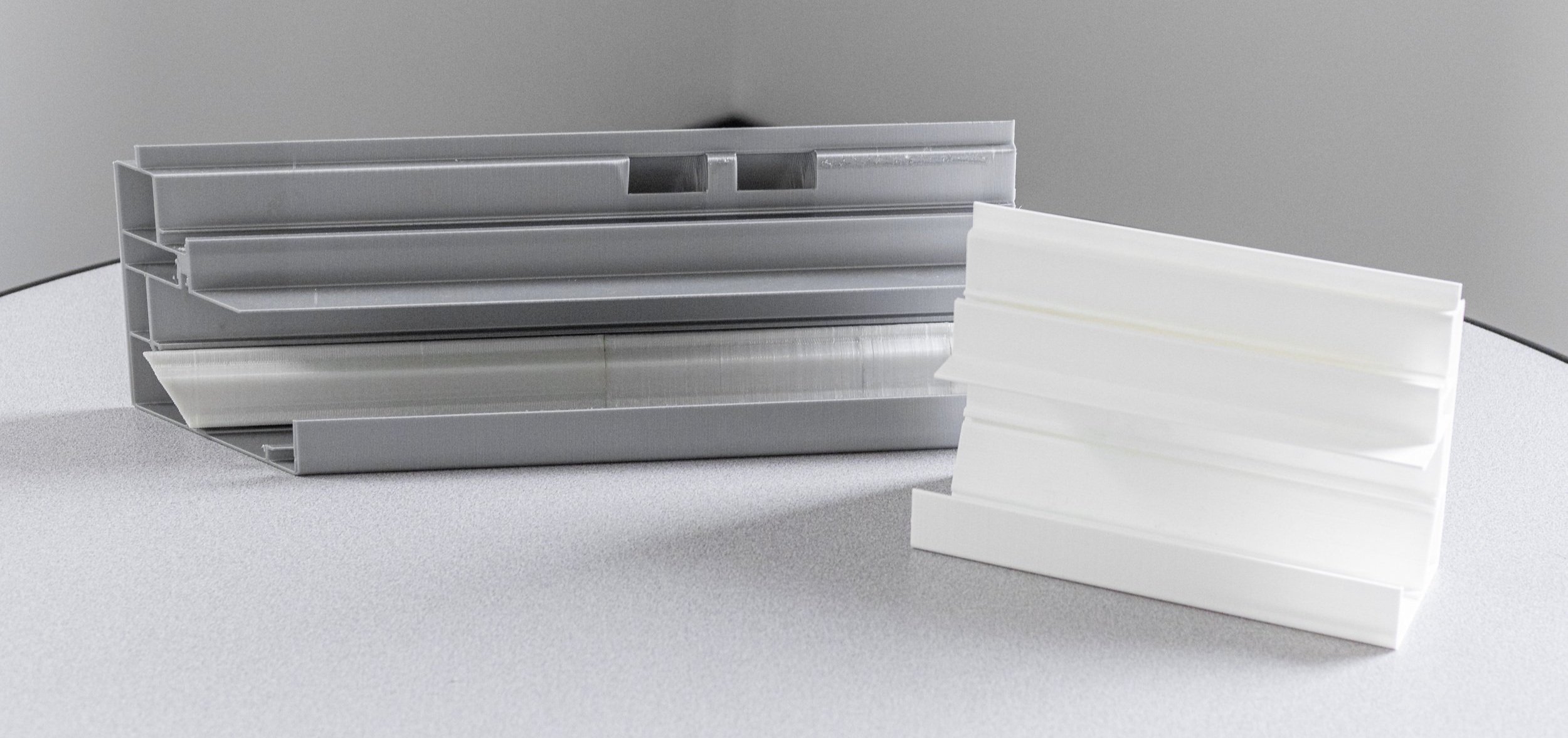

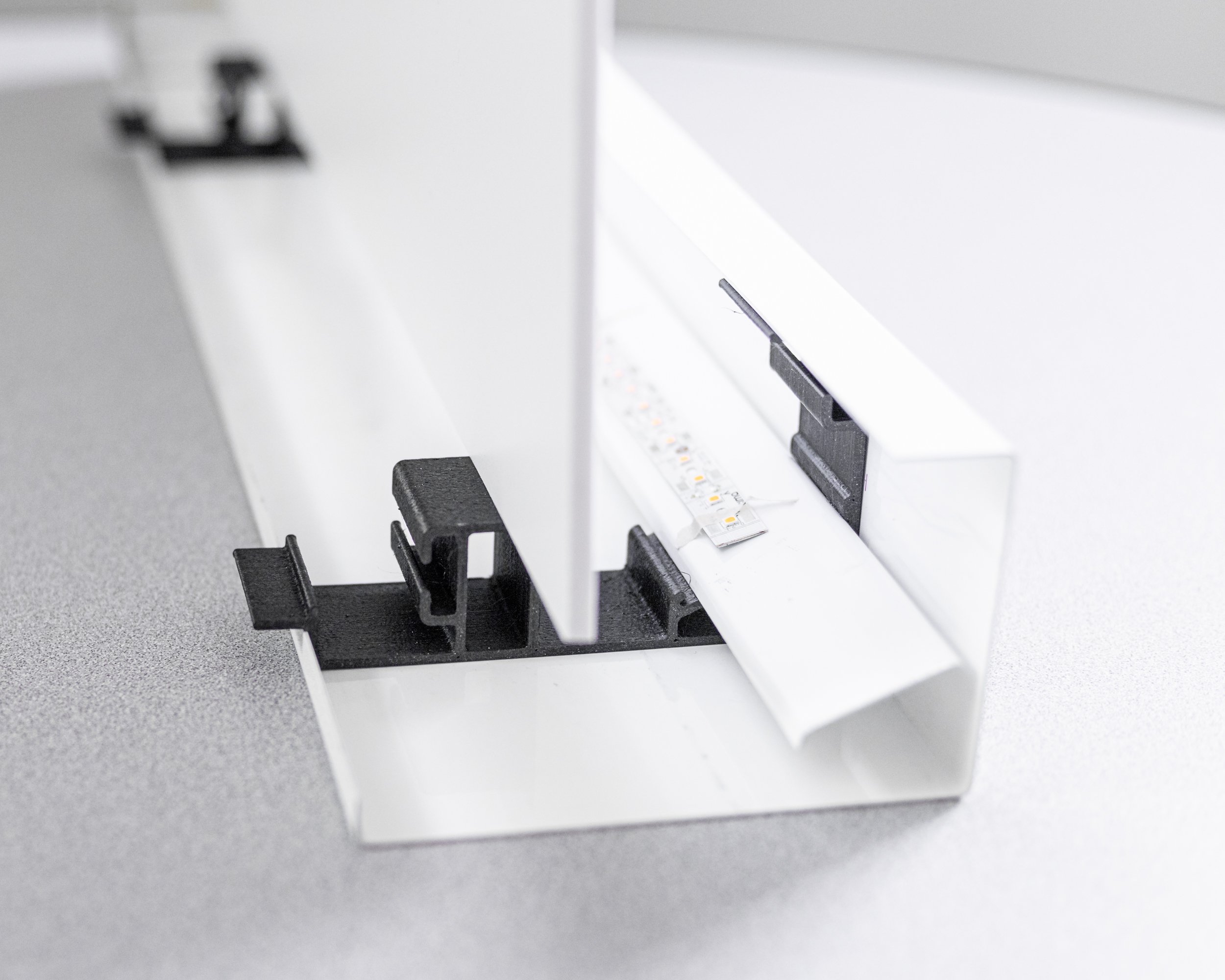

Designing the Custom Extrusion

Mocking up the basic shape of fixture with 3D printed sections to test for the correct angle of the LEDs

Testing materials for the back surface.

4’ x 4’ prototype unit being tested

Installed unit with graphic print

Manufacturing Process

Cima Cove Offshoot Projects

Cima Cove Sales Sample

Once the design of Cove was complete, I had to make a portable version to show sales reps. This was a whole project in itself since a conference table is a completely different atmosphere than a panels standard use case.

Drill Jig

In order to manufacture replicable fixtures, I had to create jigs that would create consistent results when used during assembly. All fixtures needed a wire channel drilled through the extrusion. This project shows the process of creating the 3D printed jig.

skills used in this project:

Adobe Illustrator

Adobe Indesign

Adobe Photoshop

Budgeting

Driveworks

Design for Manufacturing

Electronics Design

Extrusion Design

Marketing

Project Management

Solidworks

Sourcing / Supply Chain

Trello

Visualize