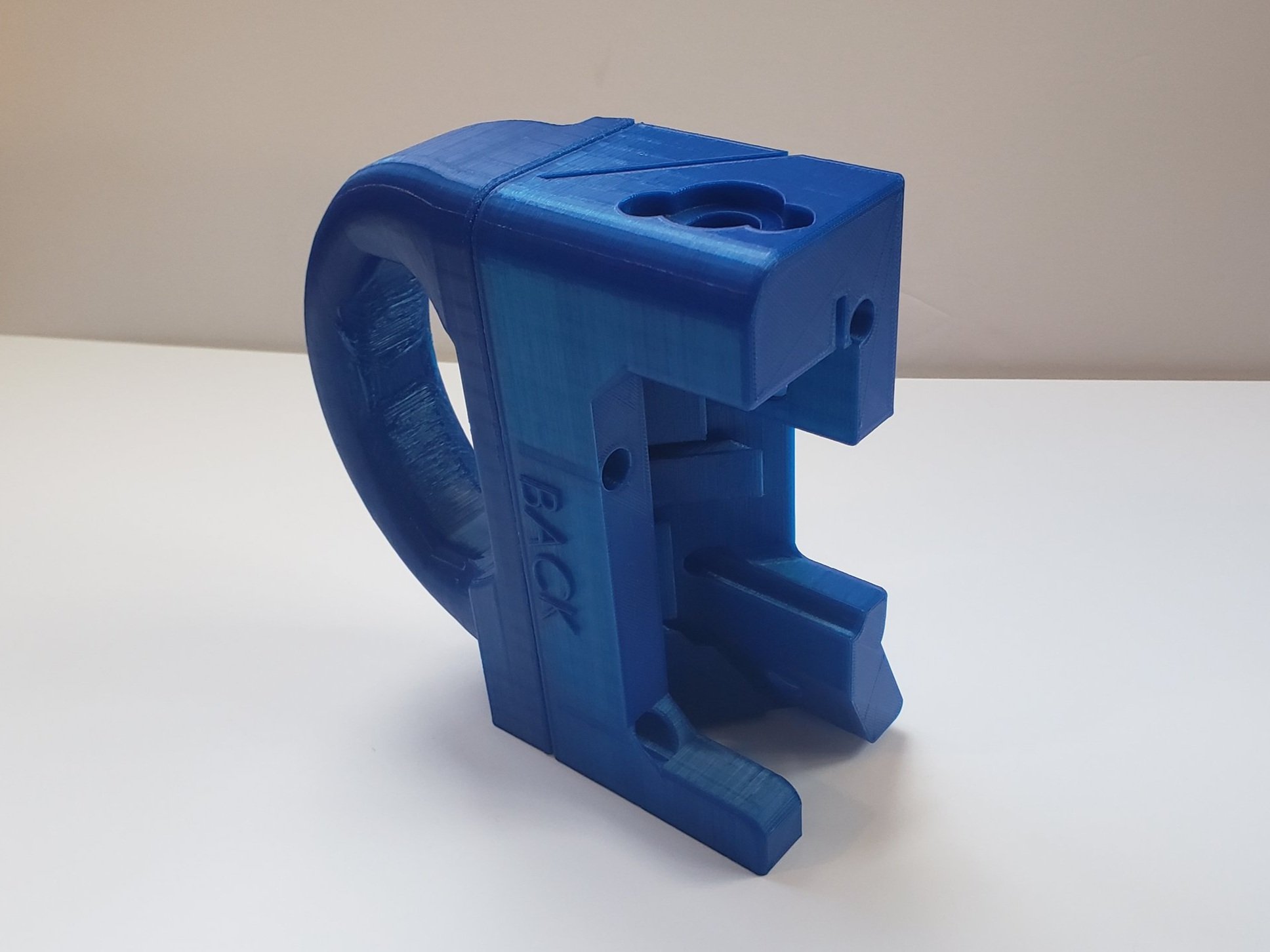

Drill Jig

Creates consistent and accurate channels for wires to pass through by guiding users drill bit

In order to pass wires through the extrusion, three perfectly aligned drills were needed

Drill Faces and Axis

Wire Channel

Guiding wire sleeve through wire channel after jig was used

Development

I made an initial concept prototype to test the fit and locations of the bushing holes.

I made some tweaks to the design and came up with a V2 before doing user testing.

The offset that worked with the 3D printed extrusion did not work for the real extrusion

The handle was too small and weak to live in the shop

The labels needed to be large and clear

User Testing

Takeaways from users:

Bushings would pop out after more than a few uses

It was confusing to initially get on the extrusion correctly

Overall, felt too fragile since it would get tossed around

After researching options, I decided to ditch the standard bushings and replace them with lockable versions held in by threaded inserts. By increasing the surface contact between the 3D print and hardware, but more importantly having the screws preventing any rotation of the bushing, this new system created strong holds during drilling.

New Version

Communicated much more with user

Felt sturdier and heftier

More comfortable and ridged handle

Had bushing improvements

Indented line shows user where to line up cut extrusion

And that brings us to the final version of the jig!